Dec. 09, 2023

Minerals & Metallurgy

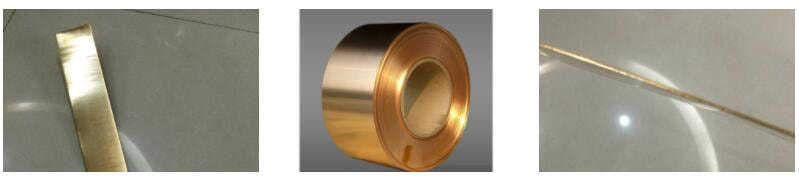

Copper alloys are used for various applications due to their unique combination of properties that make them suitable for a wide range of industrial, electrical, and decorative purposes. Here are some reasons why copper alloys are commonly used:

Excellent Conductivity:

Copper and many of its alloys, such as brass and bronze, exhibit excellent electrical conductivity. This property makes them ideal for electrical wiring, connectors, and components in various electronic devices and power transmission systems.

Thermal Conductivity:

Copper alloys also have high thermal conductivity, making them valuable in applications where efficient heat transfer is crucial. They are used in heat exchangers, radiators, and other thermal management systems.

Corrosion Resistance:

Many copper alloys, including brass and bronze, are corrosion-resistant. This resistance to corrosion makes them suitable for marine applications, plumbing, and outdoor structures where exposure to moisture and environmental elements is a concern.

Machinability:

Copper alloys sheets are generally easy to machine, allowing for the production of intricate parts and components. This makes them valuable in the manufacturing of precision instruments, gears, and other machined parts.

Ductility and Formability:

Copper and its alloys are highly ductile and malleable, allowing for easy forming and shaping. This property makes them suitable for applications requiring complex shapes, such as decorative items, architectural elements, and artistic sculptures.

Related links:Antimicrobial Properties:

Copper has inherent antimicrobial properties that can help inhibit the growth of bacteria, viruses, and other microorganisms. This makes copper alloys suitable for use in healthcare settings, touch surfaces, and other areas where hygiene is critical.

Aesthetic Appeal:

Copper alloys, particularly brass and bronze, have a distinct and attractive appearance. They are often used for decorative purposes, architectural elements, jewelry, and artistic applications.

Recyclability:

Copper is highly recyclable without losing its essential properties. This makes copper alloys an environmentally friendly choice, contributing to sustainable practices in various industries.

Strength and Durability:

Depending on the alloy composition, copper alloys can exhibit good strength and durability. This makes them suitable for structural applications, automotive components, and machinery parts.

Chemical Compatibility:

Copper alloys are compatible with a wide range of chemicals, making them suitable for use in chemical processing equipment, pipes, and containers.

In summary, the unique combination of electrical conductivity, thermal conductivity, corrosion resistance, machinability, antimicrobial properties, and aesthetic appeal makes copper composite plate versatile and valuable in numerous industries and applications. The specific alloy chosen depends on the desired properties for the intended use.

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )